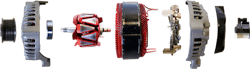

OE power and performance can be achieved well after the car leaves the assembly line. Duralast Alternators and Starters are remanufactured with 100% new professional-grade components, in state-of-the-art IATF16949-certified manufacturing facilities—not merely rebuilt. This means each unit undergoes meticulous triple-testing on proprietary computerized test equipment during the manufacturing process, from the individual components to sub-assembly and finally finished unit levels, every part is TRIPLE TESTED to ensure OE or better torque/amperage output and quality every time.

Install with total confidence and give customers the like-new quality they look for. Duralast Starters and Alternators are remanufactured with all new wear components and triple tested from component to final assembly delivering OE or better power. The Duralast line also offers Duralast Gold Starters and Alternators that are 100% new. In some applications where the OE has known design flaws, Duralast has innovated to include oil drip shields on the units to prevent premature failure. When it’s Duralast, you know you’re getting OE quality, every part, every time, for maximum ROI, safety and customer satisfaction.

What is Triple Testing and Why Is It Important?

Triple testing is the process Duralast Starters and Alternators go through to ensure performance standards are met or exceeded. The three-step process starts first with an initial sample approval to validate all components conform to the OEM standards for performance, durability and functionality with wear components being replaced 100% new. Next, all critical sub-assemblies are 100% tested on specialized test

equipment prior to final assembly. Finally, completed units are 100% individually end-of-line tested on proprietary, load-based testers across a full range of operating requirements.

Real-life category specific testing is the vetting process by which shop owners know their Duralast parts are strong, reliable, and will help ensure loyal/repeat customers and minimize comebacks.

Did You Know?

—

In the 2019 Rachet+Wrench Industry Survey, just 25% of respondents reported that their parts inventory contained no more than 29% of OEM parts, meaning more than 70% of shops' inventories consisted of aftermarket parts, such as Duralast.