Bonnie DeGrazia always prided herself on being a generous shop operator. It’s been about five years since she took over running every aspect of Vanguard Automotive Repair in San Rafael, Calif., and her goal was always to keep the customers as happy as possible, all while trying to keep cars coming in and out.

On occasion, DeGrazia would have her techs give a quick look at a customers’ car in the parking lot, free of charge. Other times, she would throw in small parts for free into a repair.

But as she worried about paying the bills—not only each month, but also week to week—DeGrazia realized she was throwing away her business.

It wasn’t until after she sought out some help that she realized her problem wasn’t necessarily her shop’s generosity; it was its productivity.

“There were lots of times where we wouldn’t charge for the extra things that happened,” she says. “I’m in the office saying this is a three-hour job, and they’re out there doing the job and it takes four-and-a-half hours, because they might see a car that all of a sudden has more problems—a lot of rust in an area, a part that breaks, a pipe that breaks in the process of doing the job. Those things happen with older cars, but we weren’t charging for that.

“Part of it was not realizing what was going on, part of it was trying to be generous to the customer. Either way, it was our productivity that was hurt. We were doing work and working hours that weren’t billed to a customer.”

Maylan Newton, an industry consultant and former shop operator, says a lack of productivity is one of the most frequent problems he sees in repair shops. Productivity issues can have many causes, and most shops don’t even realize they have them, Newton says. But there is one simple way to find out: Tracking your shop’s average hours per repair order.

“It’s just a simple calculation,” Newton says, “and it’s one of the most important numbers we focus on, one of the most important numbers that shops should track.”

Defining It

Newton says there’s a distinct difference between being busy and being productive. Example: A shop owner gives a four-hour repair order to a technician. While the tech works on the repair, the owner asks him to take another car on a test drive. Then, he wants him to explain a different repair to Mr. Johnson. Later, he pulls the tech out from under the hood to run to the parts shop. Seven hours after getting the repair order, the tech is done with the work.

“Now, the tech was busy the whole day. He worked seven out of his eight hours without a break,” Newton says, “but a customer was only billed for four hours of his work day.”

A productive shop, Newton says, has all of its labor hours billed out to customers.

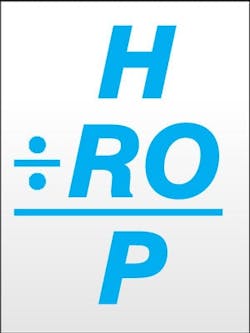

The first step is tracking the average hours per repair order (H/RO). It’s simple math: take the amount of hours worked in a week by a technician, and divide that by the amount of repair orders he or she worked on that week.

What you get, Newton says, is a number that tells the story of your shop’s productivity and, ultimately, its ability to turn a profit.

Measuring It

Newton compares tracking a shop’s finances to keeping score in sports.

“If you want to know if you’re winning or losing in sports, you have to keep score,” he says. “Business is the same way, if you’re not keeping score, then you have a little bit of a problem, because you don’t know who’s winning or losing.”

And like a sports score, having one number usually only shows half the picture. So, once a shop owner has his H/RO, they compare that to the average labor hours billed to customers on each repair order.

The goal is to have the hours billed to a customer exceed the amount of hours worked by the technician, which would make a shop’s productivity exceed 100 percent.

Hours/RO is unique to other metrics in the repair industry, as its goals are universal: A shop in Fargo, N.D., and a shop in Los Angeles strive for similar numbers. Geography, client demographics, size of shop—none of it should make a difference, Newton says.

Newton’s team of coaches with Educational Seminars Institute gives their clients a goal of averaging three repair orders—at three billable hours each—every day, giving them nine billable hours for every eight hours worked. That’s an H/RO of roughly 2.67, and a productivity rating of 112.5 percent.

A minimum—and attainable—goal is to range between 2.7 and 3.5 H/RO. The industry average, Newton estimates, is much higher. Small jobs and errand running, which are at times unavoidable, need to be made up in other areas.

Understanding It

Productivity is a problem, Newton says. He estimates that 95 percent of all shops are unproductive, meaning they are working hours not billed to customers.

Strangely, Newton says, this lack of productivity rarely has to do with a lack of effort.

DeGrazia says her shop is proof of that: They always seemed busy but, as she found out, they were not very productive.

“We had cars coming in and out all the time,” she says, “but we weren’t making money on everything we were doing.”

Newton says the reasons are extremely wide-ranging: A shop floor could be poorly laid out, making techs walk too far to get to equipment; the actual facility could be poorly designed to where cars are difficult to get in and out of the bays; it could also be pricing, errand running, test drives or, what Newton finds most often, an overstaffed shop.

Fixing It

Newton says it can be tough, sometimes, because being more productive can often mean letting go of employees who were doing what the owner thought was adequate work.

“We were in a shop where a guy had six technicians, two service advisors and him,” he says. “His techs were about 49 percent productive, all of them.

So, when you crunch the numbers, he was doing in sales what three people could do in repairs. He had twice the staff he needed to

be profitable.

“I told him, if he wanted to make money, he needed to get rid of his three weakest technicians and one service advisor.”

The shop owner was reluctant to listen. It took him a few years—and $35,000 worth of lost savings—to finally make the cuts. Ultimately, it saved his shop from going under, and he is now churning out a solid profit.

Luckily, some shops can make adjustments without cutting staff.

DeGrazia says there were three main things she changed about her operations to increase productivity:

1. Communication. “Part of this process is having the communication with our techs and myself, so that I’m aware if there’s something else that is a problem. There’s no way to know unless they come and tell me. In the past, that stuff happened and got fixed and we never charged for it, and we were losing money right and left because we were taking the time to fix a car properly but we weren’t getting paid out for it.”

2. Repair checklist. “We started having our techs make a repair checklist for every repair they did. They list all the parts and everything they did. This way I know exactly what parts and labor to charge for, and we don’t miss anything”

3. Retrain customers. “There were times when customers would come by and ask what their car needed. We’d have the tech take a quick look at the car, and that took them away from their job they were on. Now, I’ve stopped doing that and trained my customers to make appointments and let them understand we have to charge for these things.”

The Final Score

DaGrazia only started tracking her shop’s H/RO in January. Since then, she’s started to make a number of changes to her shop, including a new, up-to-date management software system and better overall repair order procedures.

“My ex-husband and I started the shop 26 years ago, and we always did things really old school,” she says. “When I took over complete control of it, I want us to get up to date and turn it into something that actually makes money.”

After only a couple months, DeGrazia says her shop is already making a solid profit because of its new levels of productivity.

And, now, instead of worrying about being seen as generous, DeGrazia is looking to be fair—both to customers and to her business.

“Now, I have much more confidence in the fact that I have a better understanding of what’s coming in money-wise and what’s going out money-wise,” she says. “I know that whatever I’m purchasing for parts is getting billed out. We’re still treating our customers well, and our goal is still to make them happy, but now we’re making sure we’re making money off the work we do.”

About the Author

Bryce Evans

Bryce Evans is the vice president of content at 10 Missions Media, overseeing an award-winning team that produces FenderBender, Ratchet+Wrench and NOLN.