Gary Dalton is a long-time expert in fleet service, with a strong emphasis on the service aspect of things. Having spent his entire career managing one company or another—always with commercial fleet as its main profit center—Dalton knew how to treat commercial clients, and how to organize a shop to efficiently turn out consistently strong work.

But, when Dalton struck out on his own and started Ultimate Fleet Repair in Eagan, Minn., he eventually ran into the same problems that many in the independent auto repair industry see daily with fleet work: unpaid bills, rolling credit and, unfortunately, carrying way too much of a financial burden for the repairs the shop was doing.

This was in 2009, and the recession had hit many local companies, including many of his clients. In fact, being laid off by his previous employer was what prompted Dalton to open Ultimate Fleet in 2008.

At the time, his business was due to generate more than $1.2 million in sales.

That’s on paper, though. In reality, Dalton wasn’t even sure how many of those bills would get paid.

“The hardest thing is always collecting money on those invoices,” he says.

It’s a problem every shop around the country faces when doing fleet work, says industry consultant Cecil Bullard, president of the Institute for Automotive Business Excellence.

But there are simple—yet incredibly important—steps that every shop can take to running fleet service effectively, Bullard says. These steps are how Dalton turned around his business, increased his profitability and is now able to collect quickly on all of his accounts.

“Fleet service can work, but only if it’s done right,” Bullard says.

Do Not Do Fleet Unless ...

Bullard regularly has clients ask about adding fleet work to their existing service centers. And he always has surprising advice: Don’t do it.

“That is, unless you’re already making money on your regular business,” he says. “In other words, you don’t build an automotive service center to add fleet work. You build your automotive service center to be an automotive service center.

“Fleet is a whole different animal. To make it work, you need it to be a fleet company, or a completely separate segment of your business.”

Bullard says there’s too long of a history of failed fleet accounts in the industry to ignore the stark contrast between doing commercial fleet work and doing general repair. Bottom line: Fleet work will not work as an add-on to your business, he says. It must be a separate profit center.

“And you really have to have the rest of your shop operating efficiently and profitably to even consider it,” he says. “It’s like any other expansion: It won’t work if you’re not in the right position for it to work.”

That Being Said ...

Dalton knows exactly how difficult it is to make fleet jobs work, but as he’s proud to say, he did—and, if done correctly, any well-organized shop can, too.

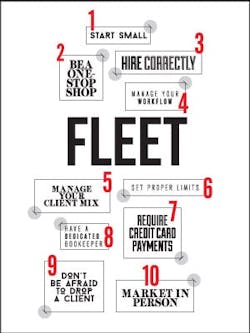

Dalton runs his shop by a number of principles he’s learned through his experiences and through working with Bullard. Together, they share their 10 tips to running a successful fleet service operation.

ONE

Start Small.

When adding anything new to your business, it can be difficult to fully understand how operations will work out, Bullard says. So, start by targeting a small account, one that can be handled by your current capacity in the shop. With this route, there’s lower risk. It’s a tryout of sorts, Bullard says, and it’s a way to build your operational structure.

TWO

Be a One-Stop Shop.

Dalton says the key to landing, and keeping, accounts is to be able to work on all of the client’s vehicles, from regular passenger cars to semi-trucks. While that’s not feasible for every shop, he strongly suggests targeting accounts where you can make that possible. Some only have pickup trucks or vans, for instance. Being the one-stop shop for your clients is critical to keeping them long term, he says.

THREE

Hire Correctly.

That’s easier said than done, but to be able to work on many different types of vehicles, you’re going to need highly skilled technicians, Dalton says. Bullard suggests, if this is an add-on to your existing shop, to have a dedicated technician for your fleet work. “The biggest thing is attitude, though,” Dalton says. “They need to be people who are excited to [work on] new things and try something new, and people who aren’t afraid to learn new things, because you’re always going to be getting something new.”

Also, mistakes and poor repairs are not easily overcome in fleet work. It’s easy for a company to drop your shop, Dalton says, so you need techs that you’re not going to be worrying about.

FOUR

Manage Your Workflow.

This all comes down to proper scheduling, Dalton says. Your clients will call when there are issues, but you should be putting them on regular maintenance schedules to ensure your bays are always full. “It’s the whole point of doing inspections [when the vehicles are in the shop],” he says. “We know they have certain issues coming up or other things they need down the road, and it’s up to us to schedule them.” Have regular reminders sent to clients, either through email or phone calls.

FIVE

Manage Your Client Mix.

Having too much of your fleet business tied to one customer is dangerous, Dalton says. “You can have a great relationship with the person you deal with, but then they can be replaced at any moment,” he says. “And maybe the new person has a cousin who does repair. You can lose that account just like that, and for no reason.”

Bullard says to make sure that no single account takes up more than 20 percent of your fleet business.

SIX

Set Proper Limits.

With the majority of fleet accounts, payment will not be instant. It’s inevitable that your shop will have to “carry” some outstanding payments from clients for a certain period of time. But, Bullard says, you need to be strict with clients on how much you’re willing to carry and for how long. Figure out a total dollar amount for outstanding payments that your business can handle, Bullard says. For Dalton, who has some very large accounts with companies like Goodyear Tire and Coca-Cola, that means he is often carrying about $150,000 of outstanding payments. “You need to find the number you’re capable of carrying,” Bullard says. “This is why you need a healthy business to do it, and it’s why you need cash reserves.” It’s not uncommon for payments to be on a 60-day cycle, but Bullard suggests getting the pay periods as short as possible, and get it in writing, or …

SEVEN

Require Credit Card Payments.

Whenever possible, both Bullard and Dalton say to get a credit card from the client to use for all work performed. There are some clients that won’t do it, but Dalton says a majority of his do, and it helps ease the shop’s financial burdens.

EIGHT

Have a Dedicated Bookkeeper.

It can be a daunting task to manage the accounts for a fleet business, and to track down outstanding payments. First off, all invoices and payments need to be handled separate from your general repair segment. And Dalton suggests having an employee at your shop dedicated solely to those fleet accounts, someone with a strong financial background.

NINE

Don’t Be Afraid to Drop Clients.

If you’ve set your limits and you stay on top of each account, but you still have clients that aren’t meeting your requirements, Bullard says to cut ties. “It’s great having a customer that can give you $30,000 of work in a month,” he says, “but if they haven’t paid in 90 days, that’s free work you’re giving them. You don’t have that money.”

TEN

Market In Person.

You clients—and competition—are very different in the fleet business; you’re dealing with companies and corporations, not independent consumers. Dalton says to identify the potential clients in your market and who the main contact with those companies would be. Then, make personal contact with them. “Usually, it’s one person that’s making these decisions for the company, and that’s the person you need to be winning over,” he says. Reach out to them by phone, or stop by their office.

About the Author

Bryce Evans

Bryce Evans is the vice president of content at 10 Missions Media, overseeing an award-winning team that produces FenderBender, Ratchet+Wrench and NOLN.