With automotive technology advancing at an ever-faster pace, running a successful repair center—especially one that welcomes all makes and models—is growing increasingly challenging.

Independent shops need a plethora of equipment, tools and training to keep up, which has caused many repairers to specialize their facilities, focusing on specific makes to reduce expenses. But there is still room for shops that want to repair a broad range of vehicles, as long as their owners are smart about where to put their money.

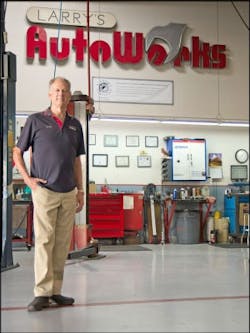

“What I see is that in 40 years, the shops that stay are going to be the ones that make the investment in their people and tools,” says Larry Moore, owner of Larry’s AutoWorks in Mountain View, Calif. “You can’t just know it now. You have to have the right equipment and be trained if you’re going to do in-depth work.”

Moore, a 40-year industry veteran whose shop repairs German, Asian and domestic vehicles, has developed a strategy for maintaining the technology needed for a broad range of repairs without breaking the bank.

Ratchet+Wrench tapped Moore and Robert Blaes, owner of Stang Auto Tech Inc. in Broomfield, Colo., which services a similar range of vehicles, to find out how they do it.

I started out building VW engines only. Then we started doing transmissions, and then we had people ask if we could work on their cars. So we kind of went the opposite direction from a lot of people. We went from being a very small niche market to expanding.

I actually had three shops at one time and we put them all under one roof. They were all three different specialty shops, so we operate as three different specialty shops under one roof. We have German cars minus Porsche, along with Asian cars and American cars. Between them all, we do just about everything.

Larry’s AutoWorks

Owners Larry, Laurie and Tiffany Moore

Location Mountain View, Calif.

Size 10,500 square feet

Annual Revenue $2 million

Total Staff 10

Repairs Per Month 240

Vehicle Types Serviced German (except Porsche), Asian, and domestic

Annual Tool and Equipment Budget $20,000

What we put out to customers is very simple: We know their vehicle. We have slogans like “Larry’s Knows Volkswagen,” or “Larry’s Knows Chevy” in our ads. We don’t market it all at once because it’s not believable.

We have specialized technicians that work on specific makes and they’re very clear about what they want to do. We find that when they like working on what we give them, they do a much better job.

Because of the number of cars we work on, we have to keep several programs updated. We spend probably between $8,000 and $10,000 a year just keeping software updates in place, software for scan tools and management systems. We use six different scan-tool systems in the shop.

There are some problems that we absolutely can’t solve unless we have the factory scan tool. What we do in those cases, quite honestly, we see so few of them, that I will pay a local shop that has that tool, to use that tool for me. I think there’s plenty of work for everybody. I don’t see there being any competitors. That’s probably a little weird point of view, but I honestly believe that for the good shops, there’s plenty of work.

Most of our daily operation is online now. We require a fast, constant Internet connection to function. We use ALLDATA, Identifix, and iATN (International Automotive Technicians Network). I think iATN is one of the most powerful diagnostic tools we use. Using other people’s collective knowledge has proven to be, in my mind, one of the most powerful tools for fixing cars. We’re on Bimmer Tech as well.

I haven’t had to own as much of the equipment personally because if we have a good group of people we interface with, then they’re going to be able to tell us where to look and save us a lot of time. The fact is in most cases, problems are not unique. Why waste our time reinventing the wheel when somebody else has already discovered it?

As with scan tools, I help keep my tool budget down by borrowing tools I’m not going to use again. I have done a split cost with other shops on a tool. Both of us wanted to have it, so we bought it and shared it. I don’t do that often, but on occasion it makes sense. Not for a scanner, though, but for things like tool kits.

I think as time goes on, unless we can see more consolidation in tools, I’m going to be more prone to do tool sharing or I’ve got to keep a big enough operation to afford tool purchases. One of the reasons we’ve grown into the size we have and why I put three shops under one roof is because it was the only way I could defend or advertise the purchase of a tool. But as long as I can handle 95 percent of the cars right here in house, I’m not going to spend a large amount of money to handle the other five percent. I’d rather pay for it as I need it.

I can’t tell people I do the best work on these cars if I don’t have the right equipment to do it. But when I say I have the right equipment, unlike some shops, I don’t feel I have to have it in my toolbox. If it’s in a toolbox down the street and it’s available to me, I have it.

In our facility, we’re not just here with the philosophy of repairing cars. We take on more of a vehicle management attitude where we’re helping the customers budget their time and money to maintain their car to meet their needs.

To do that, you have to have a strong management database so that you can give repair information in a timely basis and it can be customized for what a customer’s needs and goals are. You could have one customer say they’re only keeping a car for 60,000 miles and not doing fluid services because they can get by and not spend money. Another says I want 200,000 miles out of my car and believe in a strong preventative-maintenance plan.

You can’t always count on the same advisor taking care of the same customer and always remembering the uniqueness of the customer and that car. So you need a good management program to help you facilitate that.

Also, techs need to have the tools to deliver a valuable final product. Right now, a lot of people are holding off on investments in scan tools. In my opinion, the term scan tool has completely disappeared. A scan tool is not going to fit the bill. Unfortunately as good as some of the products are out there, one scan tool is not going to work for everything. There’s no way. Not even three are going to cover your bases, especially if you’re doing European, Asian and domestic.

Stang Auto Tech Inc.

Owners Robert and Kerri Blaes

Location Broomfield, Colo.

Size 3,000 square feet

Annual Revenue just over $1 million

Total Staff 10

Repairs Per Month 200

Vehicle Types Serviced European, Asian, and domestic

Annual Tool and Equipment Budget $20,000

It becomes cost prohibitive to buy and update factory scan tools for everything that is out there, unless you’re potentially a 12, 14, 16, or 18-bay facility and you’re seeing a large volume of that diversity. But the typical independent is anywhere from four bays to maybe 12 bays. So having all of those tools and paying the updates and subscriptions becomes cost prohibitive and many people are holding off because they’re anticipating the new technology where most of these tools are PC based.

For us, it’s a case-by-case scenario. Out of the four technicians that are here, one is a maintenance tech, the other three each have a multifunction tool at one level or another. It’s kind of indicative of their level of technical ability and has a tendency to create a ceiling on how far they advance. One Tech has a Snap-on SOLUS and one a Snap-on VERUS, which have vastly different capabilities. In my opinion a scan tool and lab scope are mandatory for each technician who is performing diagnostic testing.

We sometimes update [scan-tool software] every other year; it depends. You’re trying to foresee the future. But to pay for every update of every scan tool and have yourself covered, it would cost far more than the $20,000 a year we spend on technology and tools.

One of the ways to address technology costs is in a co-op nature. We outsource a lot of our vehicle programming where one of three people in the Denver area are mobile and come to shops like ours to provide this service. We’d be lucky if we were [reprogramming] one or two cars a month and it’s rarely the same make and model. So when you’re looking at $3,000 to $6,000 a year for the subscription on top of the hardware, how do you charge the customer enough to offset that price? If planning ahead, you can have the contractor there at the right time, and you’re only spending $50–$100 on the service.

Personally I think the bigger problem is the availability of technicians with the expertise and ability to think outside the box and utilize all of the available resources effectively. The technology and equipment is a small part of it. You have to have technicians with a strong desire to excel and provide great training for them.