Rick Hughlett has always thought a few steps ahead, or at least, he likes to operate his business that way.

He opened Rick’s Automotive with his wife in 1980 out of a 2,500-square-foot wooden building stuck on the back of a shopping strip in Springfield, Mo. The shop had rough concrete floors and sat about 300 feet off the road.

Hughlett says he wouldn’t describe that first location as “ideal” or “nice”—serviceable is more accurate.

“No matter what your shop looks like, though, it shouldn’t change how you’re going to treat customers and the type of service you’re going to give them,” Hughlett says. “We always focused on doing everything as if we were a top-notch facility, even if we didn’t have the actual facility to match it.”

RICK’S AUTOMOTIVE

Location:

Springfield, Mo.

Owner:

Rick Hughlett

Size:

26,000 square feet

Staff:

37

Annual revenue:

$5.1 million (2011)

Monthly car count:

1,100

Hughlett and his team always “did the little things” for the customers—like giving rides, dropping off vehicles, etc.—and focused on quality mechanical work to build the shop’s reputation into what it is today: a winner of Springfield’s Small Business of the Year award and a Better Business Bureau Torch Award, and one of the leading repair facilities in the region.

And, today, Rick’s Automotive has a physical building that lives up to the reputation it built over the past 30 years.

The shop’s “campus” spans nearly an entire block with three connected buildings, accounting for 26,000 square feet of shop space. The front façade features pure stainless steel panels, the customer waiting space rivals that of any luxury hotel in the area, and the shop itself is state of the art.

“If I spend a dime on my shop, it’s got to improve our ability to do a job better or quicker, or it has to make the experience better for the customers,” Hughlett says. “It can’t just be eye candy—that doesn’t help your customer at all. Every expense needs to be focused on better serving my customers.”

Hughlett, who finished his latest renovations in 2011, gave Ratchet+Wrench an in-depth look at his shop and how all the bells and whistles sound a call for better service.

Not just a façade

In 1988, Hughlett bought an 8,000-square-foot facility on his current site. It was blocked from the street by both a flea market and an O’Reilly’s store. Slowly, Hughlett bought the adjoining properties as his business grew.

He added a second building for fleet repair (his shop does service for the local hospital, a few local colleges and a number of local businesses, including the Bass Pro Shop down the street), before adding a third building dedicated to quick-service work in 2011.

It was with the last addition that Hughlett remodeled the entire facility.

Rick’s Automotive is located on a corner of a busy intersection, and since the expansion, the shop is now visible from all angles on the street. (The O’Reilly’s is still there, although with Hughlett’s facility surrounding it, the parts store looks more like a segment of Rick’s Automotive than a separate business.) And, at first glance, it appears to be one large, cohesive building, rather than three separate ones.

“All three buildings are tied together by a common drive-through area, and there’s an awning covering where folks can drop off their cars,” Hughlett says. “When we were looking to expand, I didn’t want to get other spots around town. We have a great location, and I wanted it to stay right here. So, we kind of went with this campus idea, kind of like a hospital.”

And just like any hospital, there’s plenty of directional signs to ensure customers know where to go.

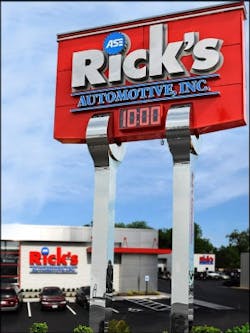

Hughlett added a massive digital sign—which stands atop 30-foot high stainless steel wrenches—on the main street out front to grab the attention of anyone passing by.

Although grand in size, the sign’s verbiage is simple: name of the shop, time and temperature.

Hughlett regularly reseals the parking lot and has the lines repainted often. He has a single line directing customers to the drop-off area, as well as signs along the drive-through and the side of the building.

“We want to make sure it’s simple to drop off your car,” Hughlett says. “With the remodel, we centralized our offices to one large one in the front of the facility, so anyone coming in for any work comes to the same place. And the drop-off area is under an awning, so they never have to go out in the weather.”

The fresh paint job, the front display window and the stainless steel panels (custom-made for his facility) all help give the shop’s façade a professional look, Hughlett says.

“It’s about building trust for the customer,” he says. “It’s easier for them to see you as a top-notch facility, if you actually look like a top-notch facility.”

Worth the Wait

With the service offices being centralized to the front of the facility, any customer for any type of service can speak with one of the shop’s six advisors for information about their vehicles, and there’s plenty of space to do it.

The waiting area itself may be the main attraction to customers, though. Hughlett had a designer who works with many of the area’s large hotels to map out the plans.

“I didn’t want it to be just what I liked,” Hughlett says. “I wanted it to be what customers would like.”

It has high-top tables, low tables, plenty of comfy seating, magazines and large flat-screen TVs. There’s free gourmet coffee, ice water and a vending machine for pop and snacks. There’s also music playing, which customers can adjust to their liking.

For customers who want some fresh air, there’s also an outside patio with seating that “looks like you’re at Sonic,” as Hughlett says of the tables with affixed bench seating. There’s music out there, too.

“Customers seem to really like it. They tell me it’s nicer than most hotels they’ve been in,” Hughlett says. “It’s just one of those things that lets them be more comfortable with doing business with us. It’s a way to show them that we care about them.”

Work Areas That Work

Going back to his days in his original shop, Hughlett has always believed that the simplest way to best serve customers is by giving them the best service possible. His new facility allows his employees to do that, not only by state-of-the-art equipment, but also with creating an atmosphere where employees like to work.

Having happy employees ultimately leads to having happy customers, Hughlett says.

The shop’s three buildings are split into three segments of the business: quick service, fleet and heavy mechanical work. Each has the latest equipment, and each has matching counters, colors, flooring and doors. “I wanted it all to have a cohesive look,” Hughlett says.

The quick-service shop, which totals 10,000 square feet, has three below-ground work stations, large enough to provide a surprising amount of space for technicians and all the tools and equipment they need while performing tasks such as oil changes.

That type of feature leads to quicker turnaround on jobs, Hughlett says, where as aspects like a 40-person conference room, which includes an oven, fridge and 72-inch flat screen set with laptop hook-ups for presentations, allow for his team to meet in a productive way. Hughlett’s 37-person staff does regular training, and the new conference room allows them to do it more efficiently.

There’s also a separate employee lunchroom and an outside courtyard with a basketball hoop, all of which is not visible to customers at the shop.

Also, Hughlett had the three buildings connected so that employees have hallways between the facilities that don’t overlap with where the customers wait.

Building a Future

About 10 years ago, Hughlett had to figure out the next step for his shop. Rick’s Automotive was busting at the seems with work, as it regularly generates more than $5 million in revenue. So, did he want to sit on the solid foundation he already built and sail ahead toward retirement, or did he want to keep building it for future generations of his family to take over?

His facility now speaks loudly about his answer.

“It was never my dream to sell it and then retire,” Hughlett, 55, says. “I decided about 10 years ago that the only goal was to carry it on for the next generation.”

One of his daughters works at the shop, as well as two sons-in-law and his brother-in-law.

Making the changes that he did to his facility required no small investment. Hughlett estimates the entire campus has cost him roughly $5 million to build, but he says it will be completely paid off within five years, especially with the increased revenue generated by the upgraded facility.

“This isn’t a business for the faint of heart,” he says. “It’s got to be something you’re really passionate about. If you’re not, your customers will sense that.

“It has to be about doing what’s best for your customers. That’s what we’ve always focused on and that’s how we built our reputation. Now, we just have a facility that matches that a little better.”

About the Author

Bryce Evans

Bryce Evans is the vice president of content at 10 Missions Media, overseeing an award-winning team that produces FenderBender, Ratchet+Wrench and NOLN.