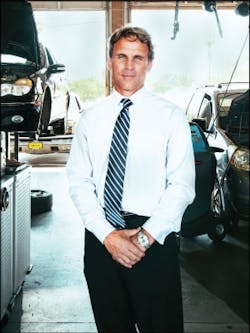

Mike Proud has a simple approach to setting his shop apart.

In every facet of his business, Proud seeks to “do more” than fix cars. Adding value beyond repairs is a focus of his, and it has worked for his shop, Exclusive Auto in Yucaipa, Calif.

Named one of the top-five businesses in the city of Yucaipa (population of roughly 51,000) by the California Senate and Legislature, the $1.5 million shop is also a three-time winner of the Celebration Media U.S. (CMUS) Talk of the Town Customer Satisfaction award for best auto repair facility in the region.

Using top-down leadership, thorough employee communication and training, as well as a pay structure that allows all employees to share in the shop’s success, Proud has inspired his team to invest in his vision and make it a reality.

“The crew … they’re an extension of the owner. The owner should not be on his own little pedestal or in his own little hole,” Proud says. “Everybody needs to be part of that.”

You Set the Mold

Proud started in the industry as a technician, working at a Mercedes dealership for many years. In 1994 he bought his shop. Ten years later, he moved into his current 4,000-square-foot building.

While growing the business, he honed one of his most essential leadership philosophies: lead by example. Although the expression is common, Proud says many owners misinterpret its meaning.

“Some people would take that as ‘I have to do everything,’ because that’s what a lot of owners like to do,” Proud says. “They’re not good executives. They’ve got to do everything, because they’re the only ones who can do it right.”

Proud approaches the subject more holistically, believing that how he presents himself and treats his employees informs his staff how to conduct themselves and treat customers.

“If you want everybody to have a great demeanor and be pleasant and smiling, well, you’d better be too,” Proud says.

Looks Matter

Overall appearance is also a priority. From the shop floor to the waiting area, the facility is a model of organization and cleanliness.

“If you walk into an auto shop and it’s filthy, and then you walk into another place and the price is the same … the immaculate one is going to get the job,” Proud says.

To further drive home the point, Proud has all of his technicians wear uniforms with white shirts, which encourages them to practice clean work. It’s a trick he picked up during his days at the Mercedes dealership.

“New technicians will come in and they’ll start and they’ll be filthy for about a few weeks, then they start learning how to get cleaner,” Proud says.

Since Proud demands cleanliness from employees, he knows he needs to live up to his own standards. He shows up at the shop every day with a uniform that fits his role as owner—a long-sleeve shirt, tie and dress pants.

According to Proud, the owner essentially leads his or her business by setting standards and adhering to those standards.

“You set the basic mold of the presence of the shop,” Proud says. “You are the face of it.”

Pull Don’t Push

In addition to leading by example, every owner has to communicate to employees how he or she wants a job done. Proud says there are two approaches.

“There’s managers that whip and push, and there’s managers that speak and pull,” he says. “Do you want leadership, or do you want dictatorship?”

Proud says the best way to encourage employees to get on board with how you want the job done is communication, which will establish what Proud refers to as “matching realities,” the point where the employee and owner’s perceptions align.

Matching realities starts with laying out the goal. For example, how a car should look when it’s completed. Once the goal is established, the next step is training.

“You don’t just tell someone,” Proud says. “You train even if you don’t think they need it.”

Proud thoroughly trains on every task an employee does.

For example, when new customers come into the shop, their information, such as how much they spend, who the service writer was and whether they were referred, gets written on a special sheet. The process is clearly laid out for staff as far as how to find out if the person is a new customer, where to find the data sheet, how to fill it out, and to make sure that person gets a thank-you card.

With every process, Proud has employees sign an agreement that they not only understand how the task should be done, but why he has them do it that way. And if Proud sees his employees slipping up, he sits down with them, has them show him how they are completing the task and explains to them where they are falling short.

“You don’t yell. You talk. You explain things. You develop the reality,” Proud says. “You tell them what the goal is—the final target, what they’re achieving and then the big thing is also praise.”

Chaunda Fanning, administrative coordinator for the shop, says that Proud’s ability to communicate is one of his strongest attributes as a leader. Jim Smith, a senior consultant for Management Success! and a friend of Proud, says setting clear instructions and expectations for employees makes any owner’s life easier, and Proud demonstrates that.

“He is very good at making sure they know what the their jobs are—how to do them—and he is setting them up to be successful,” Smith says.

Sharing in Success

Proud wanted to develop a pay system that would make every employee in the company invested in the shop’s success. From technicians to service writers to administrative coordinators to lot attendants, everyone is paid based on the performance of the shop.

Technicians and service writers receive pay incentives based on the billable hours or sales they produce. Other employees, like an administrative coordinator or lot attendants, receive bonuses in relation to the shop’s weekly gross sales.

A lot attendant at Proud’s shop has a base pay of $10 an hour, for instance. The shop’s bonus system is set in tiers of $2,000. So, at $2,000 above the break-even point—the exact dollar amount the shop requires to pay all of the bills each week—the lot attendant gets an extra $1 an hour. Two thousand dollars above that, he gets an extra $2 an hour.

“If the whole shop is doing well, you know everybody is doing this together,” Proud says. “There’s no one person, so you pay everyone accordingly.”

Proud also thinks up unique ways to show employees how specific practices make the shop more successful.

For example, the shop does 30-day follow-up calls with every customer. The service writer lays the groundwork for the call when the customer is in the shop, saying he will call back in 30 days to check in, and if there are some recommended repairs for the vehicle, he will discuss it with them at that time.

In 2010, when Proud first introduced the idea, his writers were skeptical, because they felt like they were cold-calling customers. So Proud decided to have a contest to show his writers how well the calls could work.

He took two writers and had them start doing 30-day follow-ups with their customers. The first writer to get 10 cars to return to the shop got top prize ($200), and the second-place finisher got a runner-up prize. In three weeks, the two writers combined for a total of 27 cars to come back for additional work, an extra $15,000 in revenue.

Fanning says knowing that Proud’s processes work motivates staff to continually adhere to his training.

“I see how it works,” Fanning says. “I’ve taken what he’s trained me on and I use it, and then it works, and that’s satisfaction.”

More Than Money

Although money is important, Proud says it’s nothing without the right people.

What’s essential and often overlooked in building a unified team, Proud says, is letting each employee know that you want what’s best for them.

“You tell the person, ‘look, you’re important. … I am here to nurture and help your position in every way I can,’” Proud says. “And that is something that has to come across.”