For more than 25 years, Doug Hillmuth has used standard operating procedures (SOPs) in his shop. Yet, he can still remember what it was like to work without them.

“It’s chaotic,” says Hillmuth, who along with his brother, Bill, founded Hillmuth Certified Automotive in 1978 in Columbia, Md. “And it’s extremely hard to be efficient without them.

“You can get away with it when you’re a smaller shop, but if you’re trying to grow or expand or become more efficient, you have to have them in place.”

Hillmuth and his brother first officially implemented SOPs into their business in 1986, when they opened their second location in Gaithersburg, Md. Before that, it was more informal—they knew the processes, he says, and they were small enough still to where they didn’t feel the need to write anything down.

“My brother and I were still turning wrenches in those early years,” Hillmuth says. “The technicians in us were always looking for the most efficient ways to do things, and our procedures just came off that.

“But you reach a point where you’re growing, and you have more people coming in, and you want more freedom in your business. That’s what SOPs give you; they give you that freedom in your business. Creating, documenting and implementing SOPs, it crafts the culture of your shop. Everyone knows what to do, and how and when to do it. That’s where your freedom comes in.”

And that’s where success can come in, too. The Hillmuth brothers now manage roughly 40 employees in their four shops west of Baltimore, which totaled $5.5 million in revenue last year.

It’s their strict adherence to SOPs that has made their business an industry standard, says consultant Gary Gunn, who’s worked closely with the shop over the years. “They are truly masters of the SOP process,” Gunn says.

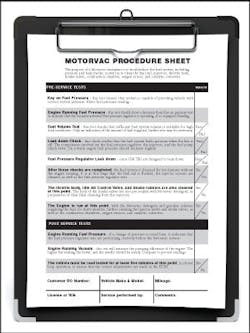

Hillmuth broke down that process with Ratchet+Wrench, using one of his shop’s SOPs as an example:

1) Anything and Everything Every aspect of your business should have an SOP, Hillmuth says, from the way you open the shop in the morning to how you check equipment to how you answer the phone. It needs to be written, recorded and distributed in hard copy to every employee in the form of a procedure manual. It acts as your shop’s “how-to” guide that needs be followed every single time a task is performed.

2) Explain the Why Hillmuth says it’s key to have employees understand why SOPs are put in place, and why tasks should be performed in that way. Often, he says, his SOPs are created with the help of the employee carrying it out. If not, Hillmuth says to explain the purpose thoroughly to the employee before implementing it.

3) Before, During and After Processes don’t start once the tech turns a wrench, or the service advisor answers the phone, Hillmuth says. There are aspects of the task that lead up to it—and that need to be performed afterward. Consider everything involved in the task, and include it in the SOP. In the case of this example, it includes all the lead up to the actual testing.

4) Focus on Efficiency The steps, and the order they’re in, comes from a bit of trial and error, Hillmuth says. “You’re focusing on what makes it efficient,” he says. “What’s the best method of getting it done? If we miss this, what’s it going to cost? How much time do we waste walking around the car, grabbing tools? Be sure to look at everything.”

5) Understand Results In this portion, Hillmuth spells out what certain results mean. It’s a way of preventing mistakes and misunderstanding—even if, in some cases, the results are obvious to a trained technician.

6) Put It to Use This form is to be used and filled out with every Motorvac treatment. “That’s how you ensure efficiency,” Hillmith says. “If they are using the sheet, the procedure, it’s all but guaranteeing they’ll follow it. What’s the point of doing it all if you’re not going to use it?”

What is an SOP?

Standard operating procedures are essentially your shop’s “best practices,” says industry consultant and SOP guru Cecil Bullard. They give a systematic way of completing a task—often in the form of a checklist.

Why SOPs?

Bullard says there are critical benefits from your staff knowing exactly how to perform their tasks.

• It improves employee performance by reducing mistakes and confusion, which in turn, creates higher efficiency levels.

• It allows managers to identify problems easier, as they can look to the process to see where the failure occurred

• It allows managers to manage, leaders to lead, and owners to focus on higher-level aspects of the business, eliminating any “babysitting.”

About the Author

Bryce Evans

Bryce Evans is the vice president of content at 10 Missions Media, overseeing an award-winning team that produces FenderBender, Ratchet+Wrench and NOLN.